SIPs

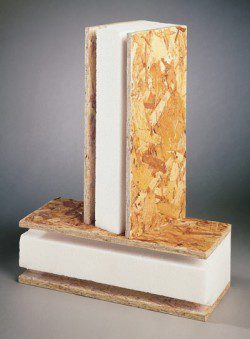

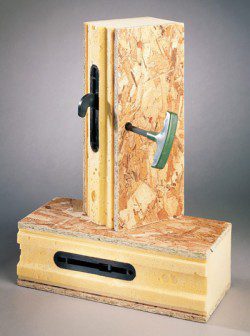

Structural insulated panels (SIPs), also known as foam core or stress-skin panels, are a highly energy efficient and superior alternative to stud-frame construction. These wall and roof panels are custom fabricated for every Sunlight home design. They are factory-built under controlled conditions which increases the quality and precision of the finished product. Door and window openings are precut using state-of-the-art CNC (Computer Numerical Control) computerized cutting equipment which ensures square and level openings.

The structural insulated panels (SIPs) are shipped flat on a truck to the building site where they are assembled like a big jig saw puzzle, resulting in a highly insulated, tight, precise, finish-ready structure. Because SIPs have the insulation and sheathing built in, there is less on-site assembly, which means a more predictable, higher quality result. In comparison, a site-built, frame structure has many site-related variables such as weather and the skill level of the building crew. There are many more pieces to assemble, opening the project up to more variation. It's worth considering structural insulated panel construction if you are interested in a well built, energy efficient, comfortable, green home.

Structural insulated panel construction contains much less wood than conventional construction because using polyurethane panels means that there are no studs. The only lumber used in the panels is oriented strand board (OSB), a structurally-rated sheathing material made from fast-growing, renewable, self-regenerating forests or plantation-grown trees. Traditional stud frame walls have many drawbacks such as “thermal bridging”, which is the heat that escapes through the gaps in the insulation created by the wood structure of the wall. A 2x6 at 16” on center stud frame wall insulated with R-19 batt insulation actually performs at around R-14 when you take into account the loss of insulation due to the walls structure. If the house was not built as air tight as possible (something that is difficult with traditional framing) you can see even lower insulating values as well as a host of moisture and health concerns.

SIPs eliminate the vast majority of these thermal bridges, meaning the stated R-value is very close to how it will actually perform in the field. If installed correctly, SIPs are also extremely air tight, alleviating the associated thermal, moisture and health problems caused by unwanted air infiltration. Despite containing less wood, polyurethane structural insulated panels are much stronger than conventional frame construction because they are a membrane structure, which effectively functions like an I-beam. The load is carried in the skins (the OSB), hence the name stress skin panels. Murus's OSB manufacturer is a member of the Sustainable Forestry Initiative.

The insulating core of SIPs are made from either polyurethane or polystyrene foam. Murus makes both. There are significant differences between the two types of foam. Polystyrene (white foam "coffee cup" material) has an R value of 3.85 per inch, compared to 6.76 per inch in polyurethane panels. Polystyrene is a thermoplastic. When heated to high temperatures, as in a fire, thermoplastic materials melt. Polystyrene panels are much more common and are manufactured in many locations across the country because the manufacturing process is easier and cheaper. Sheets of styrene foam are simply glued to skins, usually OSB. As a result, polystyrene panels are less expensive than polyurethane panels, and more readily available.

The insulating core of SIPs are made from either polyurethane or polystyrene foam. Murus makes both. There are significant differences between the two types of foam. Polystyrene (white foam "coffee cup" material) has an R value of 3.85 per inch, compared to 6.76 per inch in polyurethane panels. Polystyrene is a thermoplastic. When heated to high temperatures, as in a fire, thermoplastic materials melt. Polystyrene panels are much more common and are manufactured in many locations across the country because the manufacturing process is easier and cheaper. Sheets of styrene foam are simply glued to skins, usually OSB. As a result, polystyrene panels are less expensive than polyurethane panels, and more readily available.

Polyurethane SIPs are a better quality product than polystyrene SIPs. Polyurethane foam has been used extensively for decades in projects small and large. It is safe to humans and the environment. It does not contain formaldehyde or CFCs. Once cured, urethane is an inert, thermo-set material that does not support combustion. It has a Class 1 fire rating, the best available and rather than burn or melt it simply chars. Several of our past clients with chemical sensitivities have tested samples of urethane panels (even to go as far as to sleep with a sample of one!). Not one has ever had a reaction. We like polyurethane structural insulated panels because of their high R-value, fire resistance and thin profile. In a nutshell, polyurethane SIPs do their job better, in a smaller amount of space.

Polyurethane SIPs are a better quality product than polystyrene SIPs. Polyurethane foam has been used extensively for decades in projects small and large. It is safe to humans and the environment. It does not contain formaldehyde or CFCs. Once cured, urethane is an inert, thermo-set material that does not support combustion. It has a Class 1 fire rating, the best available and rather than burn or melt it simply chars. Several of our past clients with chemical sensitivities have tested samples of urethane panels (even to go as far as to sleep with a sample of one!). Not one has ever had a reaction. We like polyurethane structural insulated panels because of their high R-value, fire resistance and thin profile. In a nutshell, polyurethane SIPs do their job better, in a smaller amount of space.

During manufacture, polyurethane (a two-part, epoxy-like foam) is injected between two OSB skins. The OSB skins are held in a press as the foam expands to fill the cavity. As the urethane cures, it forms a mechanical bond with the skins, creating an incredibly strong, monolithic structure. The resulting SIP panel is like a three dimensional I-beam with foam instead of webbing. Polyurethane panels are much stronger than frame construction or polystyrene structural insulated panels because of the mechanical bond that forms between the skins and the foam due to the pressure exerted by the expanding foam. The machinery used to manufacture polyurethane SIP panels is more sophisticated and costly than the process used to make polystyrene panels. For that reason there are only a few polyurethane SIP manufacturers in the US.

We are not affiliated with any manufacturing system. This allows us the flexibility to choose whatever system best fits our needs. We could purchase styrene panels more conveniently and for less, but we prefer to use Murus's polyurethane SIPs because of the quality of their product, their integrity and their customer service, which has impressed us for over 25 years. Having a long-term working relationship with one panel company allows us a higher level of consistency, predictability and quality in our end product.

Polyurethane structural insulated panel residential construction has been around for decades. At Sunlight Homes we have used polyurethane panels as our primary building method with great success for over 30 years. Ask an engineer about structural insulated panel (SIP) construction and you are sure to hear great things!

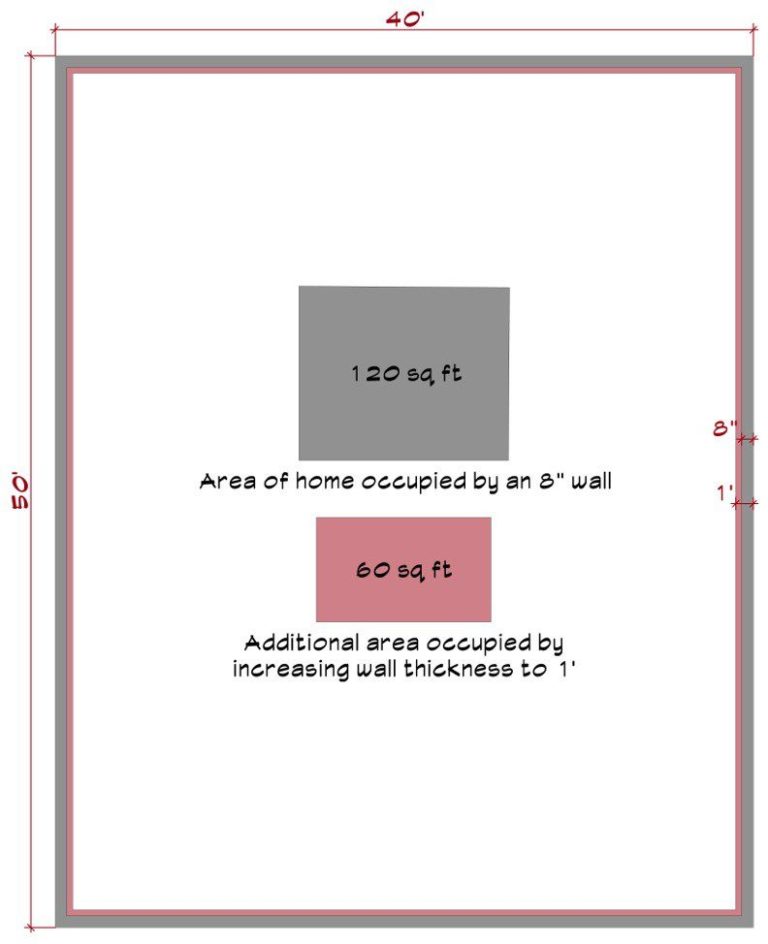

The square footage of a house in the US is taken from the outside perimeter. The thicker your wall system, the more area is taken up by wall, leaving less usable square footage. It’s surprising how much space is taken up by a thick wall compared to a thinner, more efficient wall. Even in a relatively compact design, the amount of space taken up by the perimeter walls is significant. Here is an example to illustrate the point: Imagine a 2,000 square foot house that is a simple 40’x50’ rectangle. This very compact house would have a perimeter of 180 lineal feet. If your wall system is 8” thick, the exterior walls would take up 120 square feet. If you bump that exterior wall thickness by only 4” to 1’, the overall area that the exterior walls take up is 180 square feet. That is 60 square feet of space being taken up by exterior wall that could be better utilized. Most of our homes have a good deal more exterior wall area than a simple rectangle so this difference in usable area would be even more dramatic. With this in mind, it makes sense to prioritize thinner wall sections that are still able to provide high insulating values. Our super insulated, polyurethane, structural insulated panels (SIP) wall and roof system deliver the highest insulation value per inch of any conventional insulation material. This makes for a very well-insulating wall that is as thin as possible, meaning more usable space inside the home.

The square footage of a house in the US is taken from the outside perimeter. The thicker your wall system, the more area is taken up by wall, leaving less usable square footage. It’s surprising how much space is taken up by a thick wall compared to a thinner, more efficient wall. Even in a relatively compact design, the amount of space taken up by the perimeter walls is significant. Here is an example to illustrate the point: Imagine a 2,000 square foot house that is a simple 40’x50’ rectangle. This very compact house would have a perimeter of 180 lineal feet. If your wall system is 8” thick, the exterior walls would take up 120 square feet. If you bump that exterior wall thickness by only 4” to 1’, the overall area that the exterior walls take up is 180 square feet. That is 60 square feet of space being taken up by exterior wall that could be better utilized. Most of our homes have a good deal more exterior wall area than a simple rectangle so this difference in usable area would be even more dramatic. With this in mind, it makes sense to prioritize thinner wall sections that are still able to provide high insulating values. Our super insulated, polyurethane, structural insulated panels (SIP) wall and roof system deliver the highest insulation value per inch of any conventional insulation material. This makes for a very well-insulating wall that is as thin as possible, meaning more usable space inside the home.

A key benefit of SIPs is the fact that the majority of the quality control of the product is built into the system. With other alternative building materials and systems the success or failure of the assembly is much more dependent on the workers in the field assembling the different components correctly. Some of these construction details can achieve similar results as SIPs, but often times require a much greater attention to detail and care and they might require very different construction processes than the workers are accustom to. Mistakes as simple as choosing the wrong type of caulking or the wrong type of building tape can mean a failure of the assembly to function as desired. If you have ever built a house, you know how easily these types of mistakes can and do happen, even with good supervision by a contractor that takes these details seriously (and they are a minority). If built incorrectly, some assemblies can have major thermal, and moisture issues that can not only cause higher heating and cooling bills but also lead to mold and rot issues. These problems can jeopardize the durability and structural integrity of a house as well as pose serious hazards to the occupants health.

Assembling a SIP home requires very similar tools and knowledge as a traditional frame house. Any framer that can build a traditional frame home will have very little difficulty assembling a SIP home. Because SIPs come pre-cut and ready to install, there is actually less on site cutting and assembly required. If erected correctly SIP homes function as well if not better than all of the best building systems available. They are tight, extremely strong, durable and energy efficient. All a builder has to do is follow the simple installation instructions and the home will function exactly as it should. SIPs have the added architectural benefit of easily creating vaulted ceilings, dormers, sleeping lofts and other architecturally pleasing spaces that can be an even greater challenge to build traditionally with regards to building science best practices.